1) Introduction

What is Warehouse Layout Design?

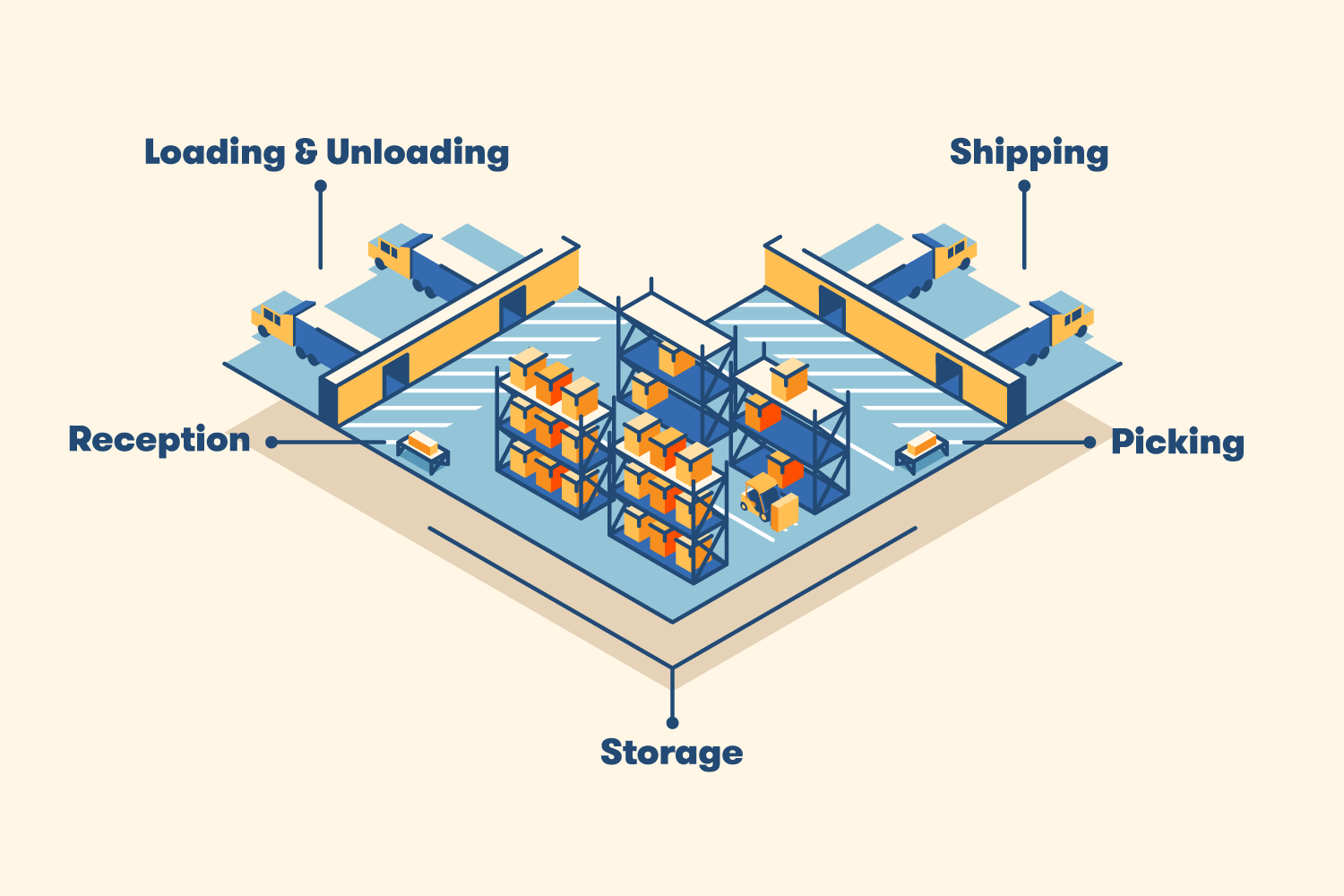

Warehouse layout design involves strategically organizing the physical space within a warehouse to optimize operational efficiency and productivity.

Importance of an Efficient Warehouse Layout

An efficient layout ensures smooth workflows, minimizes errors, and maximizes space utilization, contributing to overall business success.

2) Understanding Space Utilization

Utilizing Vertical Space

Exploring the benefits of vertical storage solutions to make the most of available warehouse height and increase storage capacity.

Aisles and Racking Systems

Design considerations for aisles and racking systems to facilitate easy access to inventory and streamline picking processes.

Storage Bin Optimization

Strategies for optimizing storage bins to enhance accessibility and create an organized inventory system.

3) Flow and Accessibility

Importance of Smooth Workflow

Highlighting the significance of a streamlined workflow for efficient order processing and reduced lead times.

Designing Clear Aisles

Tips for designing clear and navigable aisles to enhance accessibility and minimize the risk of accidents.

Accessibility for Forklifts and Equipment

Ensuring the warehouse layout accommodates the movement of forklifts and other equipment for seamless operations.

4) Zoning for Efficiency

Segregation of Storage Zones

The benefits of segregating storage zones based on inventory characteristics to enhance efficiency in picking and stocking.

Bulk Storage vs. Pick Zones

Understanding the distinction between bulk storage and pick zones and their role in optimizing storage and retrieval processes.

Packaging and Shipping Zones

Designing dedicated areas for packaging and shipping to expedite order fulfillment and improve logistics.

5) Safety Measures in Layout Design

Emergency Exits and Evacuation Routes

Prioritizing safety with well-defined emergency exits and evacuation routes to ensure a secure working environment.

Proper Signage and Markings

The importance of clear signage and markings to guide personnel and prevent confusion in the warehouse.

Adequate Lighting and Visibility

Enhancing visibility through proper lighting to reduce errors and create a safer working environment.

6) Technology Integration

Role of Technology in Layout Design

Exploring how technology, such as RFID and barcode systems, can enhance inventory tracking and overall efficiency.

Warehouse Management Systems (WMS)

The pivotal role of WMS in optimizing warehouse operations, from inventory management to order processing.

Automated Material Handling Systems

Understanding the benefits of automated systems in material handling for increased efficiency and reduced manual errors.

7) Flexibility in Design

Adapting to Changing Inventory Needs

Designing a flexible layout that can adapt to fluctuations in inventory volume and product characteristics.

Scalability for Future Growth

Considering scalability to accommodate business growth without compromising operational efficiency.

Modular Layouts for Easy Modification

Implementing modular design principles for easy modification and reconfiguration of the warehouse layout as needed.

8) Employee Ergonomics

Designing Workstations for Comfort

Prioritizing employee comfort with ergonomically designed workstations to enhance productivity and well-being.

Training and Familiarity with Layout

Investing in employee training to ensure familiarity with the warehouse layout and optimal utilization of space.

Reducing Fatigue and Enhancing Productivity

Implementing strategies to reduce employee fatigue, such as ergonomic equipment and well-designed break areas, to boost overall productivity.

9) Environmental Considerations

Sustainable Design Practices

Incorporating sustainable design practices to minimize the environmental impact of warehouse operations.

Energy-Efficient Lighting and Heating

Optimizing energy consumption through the use of energy-efficient lighting and heating systems.

Waste Management within the Warehouse

Implementing effective waste management strategies to promote environmental sustainability.

10) Case Studies: Successful Warehouse Layout Designs

Examining Real-world Examples

Analyzing successful warehouse layouts from various industries, highlighting their key features and benefits.

Lessons Learned from Industry Leaders

Drawing insights from industry leaders and their experiences in optimizing warehouse layouts for maximum efficiency.

11) Common Mistakes to Avoid

Overlooking Safety Protocols

Highlighting the risks associated with overlooking safety protocols and the potential impact on both employees and operations.

Ignoring Workflow Analysis

Emphasizing the importance of regularly analyzing and optimizing workflows to prevent bottlenecks and inefficiencies.

Neglecting Technology Integration

Discussing the consequences of neglecting the integration of technology in warehouse layout design and its impact on competitiveness.

12) Cost-Benefit Analysis of Design Investments

Initial Investment vs. Long-Term Gains

Conducting a cost-benefit analysis to weigh the initial investment in warehouse layout design against the long-term gains in efficiency and productivity.

Calculating Return on Investment (ROI)

Exploring methods for calculating the return on investment to evaluate the success of the implemented warehouse layout.

14) Future Trends in Warehouse Layout Design

Robotics and Automation

Examining the increasing role of robotics and automation in reshaping warehouse layout design for enhanced efficiency.

AI-driven Predictive Analytics

Discussing the integration of AI-driven predictive analytics for better decision-making and proactive optimization of warehouse operations.

Sustainable Practices on the Rise

Exploring the growing trend of incorporating sustainable practices into warehouse layout design to align with environmental goals.

15) Challenges in Warehouse Layout Design

Balancing Space and Efficiency

Addressing the challenge of finding the right balance between maximizing storage space and maintaining operational efficiency.

Keeping Up with Technological Advancements

Recognizing the ongoing challenge of staying abreast of technological advancements and integrating them into warehouse layouts.

Compliance with Regulatory Standards

Navigating the complexities of ensuring warehouse layouts comply with industry regulations and standards.

Conclusion

Recap of Key Considerations

Summarizing the key considerations discussed in optimizing warehouse layout design for efficiency.

Continuous Improvement in Warehouse Design

Emphasizing the importance of an ongoing commitment to continuous improvement in warehouse design to adapt to evolving business needs.